Snoopy cittern tatoo

Message from Bill Barfield

Bill bought his cittern from me in the distant past, he tells me it was 36 years ago. Today I received the following message from him:

Hi, Stefan,

I thought I’d share a picture with you. At age 64 I decided to get a tattoo. Yes, it is dumb. But I decided to do it anyway.

They say that when you get a tattoo it needs to be something important to you that will not change in the future. My cittern is one of those things. Also, I’ve always been a fan of the Peanuts comic strip and Snoopy in particular. So I put them together for a tattoo that is really me. See the attached picture.

Anyway, Thanks for all the years of joy it has given me. Have a great Christmas season.

Regards,

Bill Barfield

Charlotte, NC

It’s a while since I’ve seen it, but I also loved the Peanuts comic strip. This is a great tattoo.

Heel block stamped 57th MS model, serial no 521, Anniversary Model 8

Heel block stamped 57th MS model, serial no 521, Anniversary Model 8 Neck, body and wedges ready for assembly

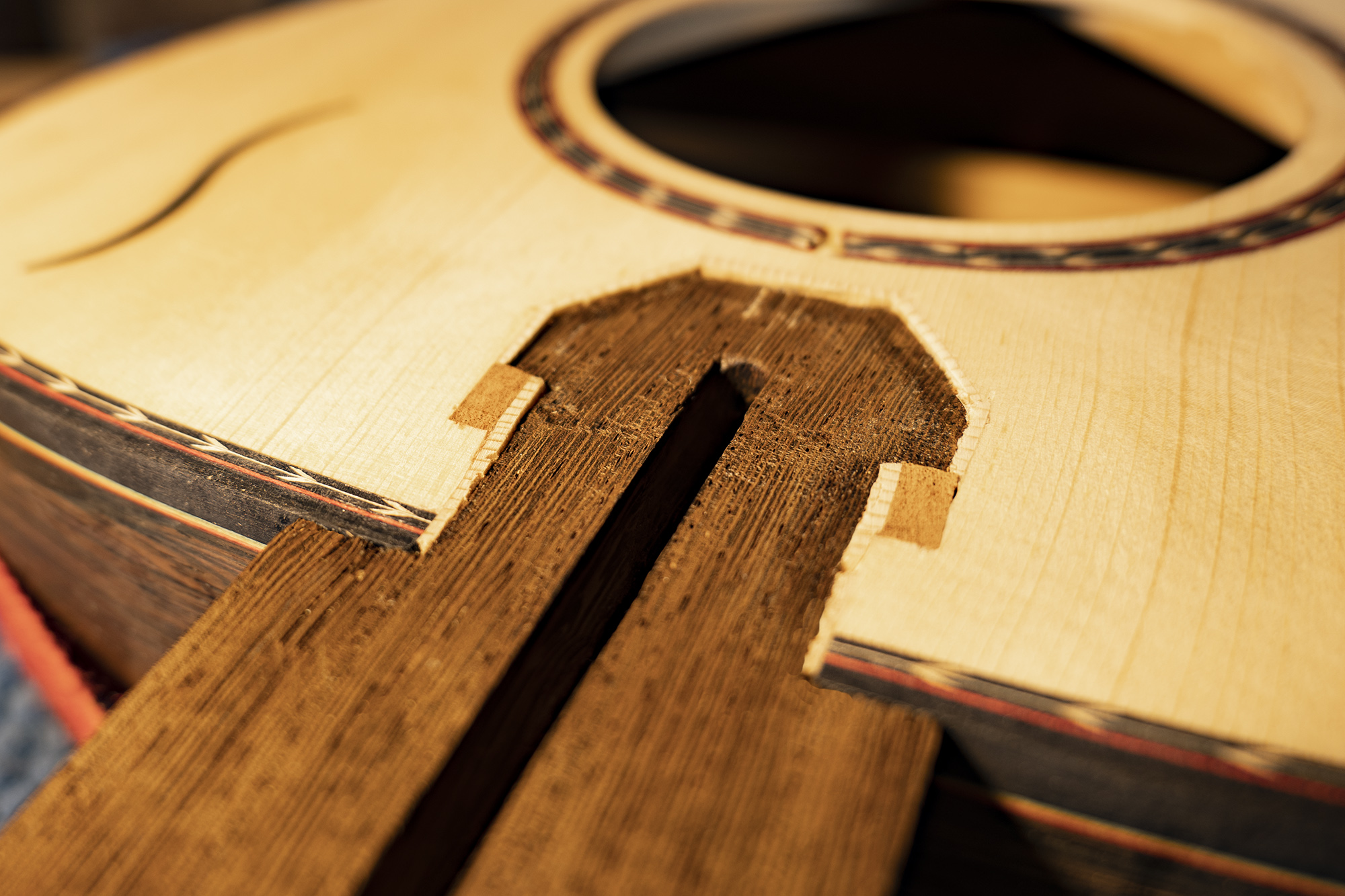

Neck, body and wedges ready for assembly Neck in place, mahogany wedges driven in and neck locked against the soundboard with little spruce wedges

Neck in place, mahogany wedges driven in and neck locked against the soundboard with little spruce wedges The last process: gluing on the ebony heel cap. Now it stands overnight before I begin fitting the fingerboard

The last process: gluing on the ebony heel cap. Now it stands overnight before I begin fitting the fingerboard Fingerboard fitted and (some time later) Wengé neck shaped. Wengé is tricky to work. The grain runs both ways, when planing or chiseling, there is always grain against you so the blade wants to dig in. It’s abrasive, so quickly blunts tools used on it, and the dust is not good. If you get a splinter it should be taken out soon; left in, the flesh around it will fester.

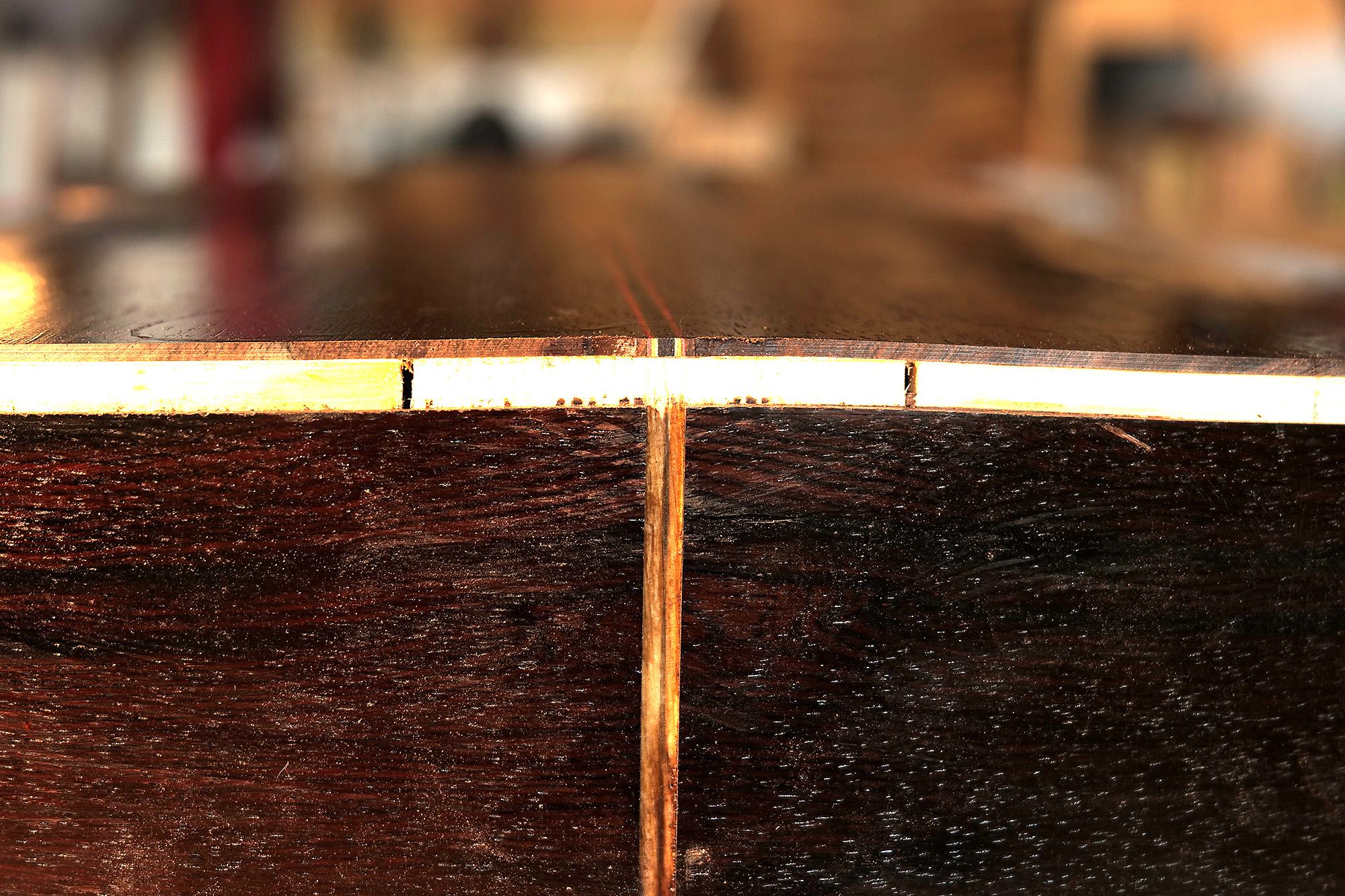

Fingerboard fitted and (some time later) Wengé neck shaped. Wengé is tricky to work. The grain runs both ways, when planing or chiseling, there is always grain against you so the blade wants to dig in. It’s abrasive, so quickly blunts tools used on it, and the dust is not good. If you get a splinter it should be taken out soon; left in, the flesh around it will fester. Top stepped ledge for binding and arrowhead trim plus red pinstripe

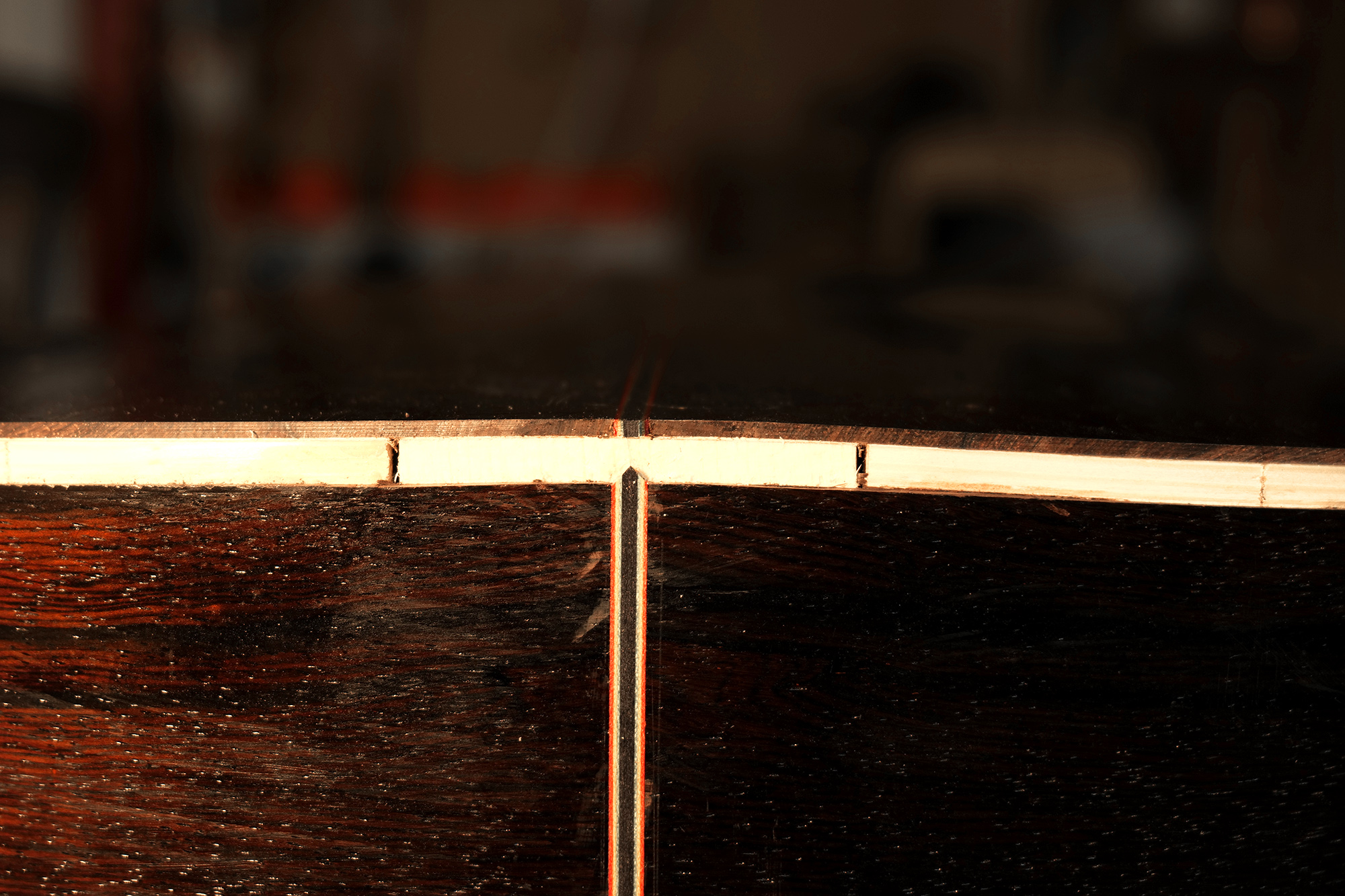

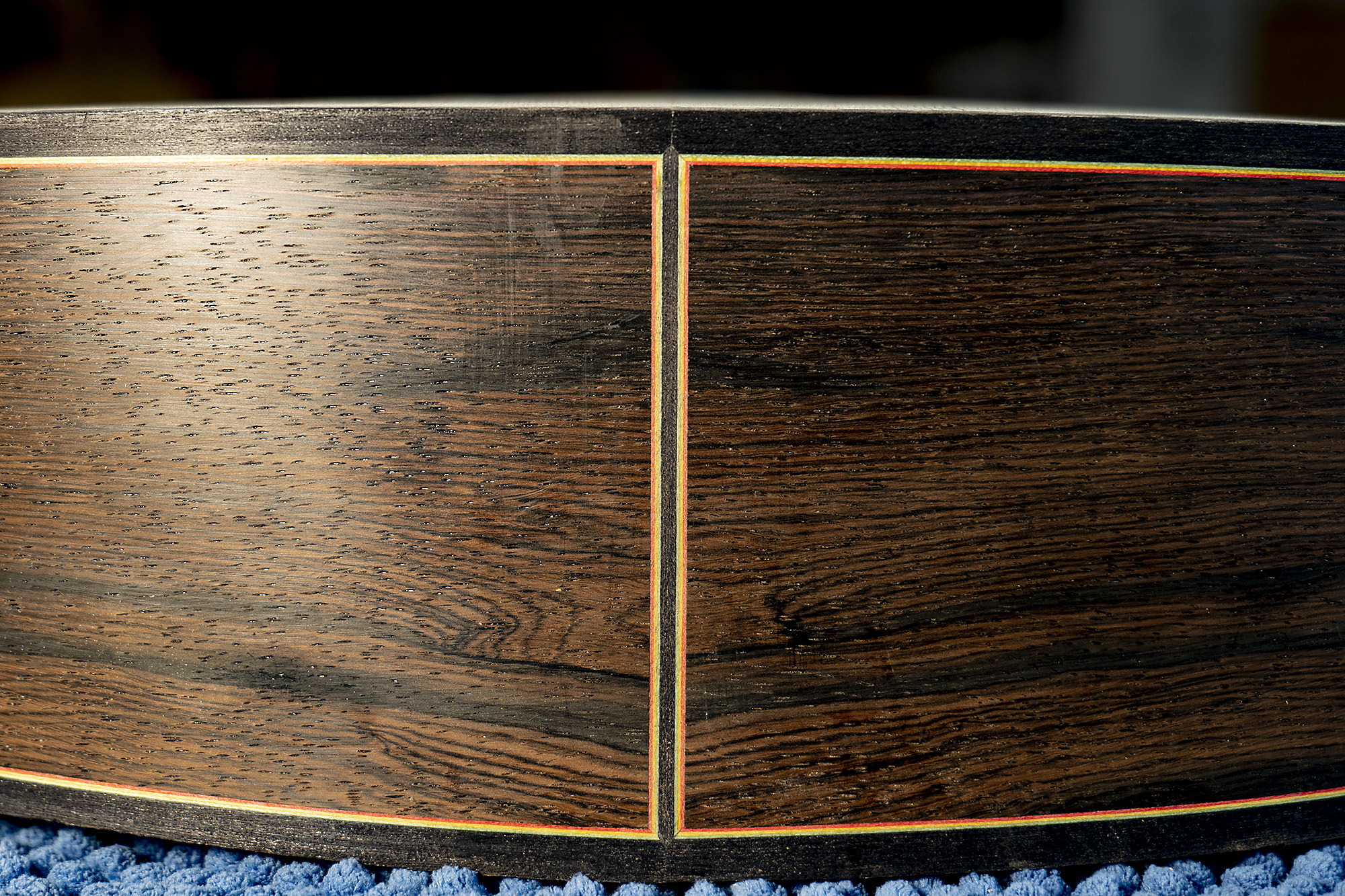

Top stepped ledge for binding and arrowhead trim plus red pinstripe Bottom stepped ledge for binding and three colour trim

Bottom stepped ledge for binding and three colour trim Sacrificial wood in place

Sacrificial wood in place Sacrificial wood removed

Sacrificial wood removed Final trim in place and mitred

Final trim in place and mitred Tail trim mitred into the binding

Tail trim mitred into the binding

Back and soundboard finished

Back and soundboard finished Lining clamped with strong spring clamps

Lining clamped with strong spring clamps Soundboard clamped to sides with cam clamps

Soundboard clamped to sides with cam clamps Back and sides with coat of shellac lacquer

Back and sides with coat of shellac lacquer After hand bending, wetting the sides and leaving them in gentle overnight heat fixes the shape

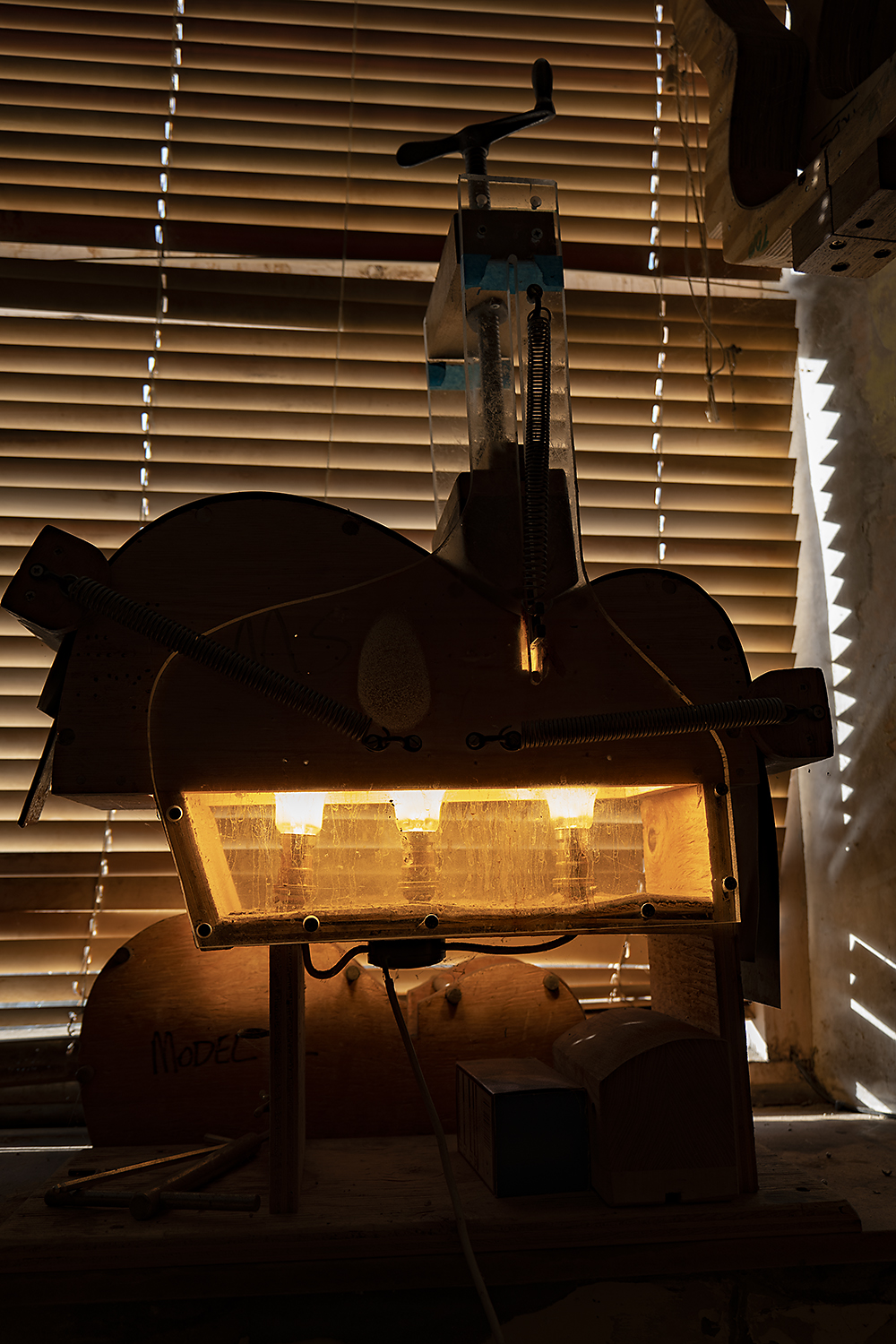

After hand bending, wetting the sides and leaving them in gentle overnight heat fixes the shape The ancient Fox bender heated by bulbs

The ancient Fox bender heated by bulbs Laminated spruce tail block fitted, mahogany heel block gluing

Laminated spruce tail block fitted, mahogany heel block gluing

2. Braces gluing in go-bar jig

2. Braces gluing in go-bar jig

3. Back and braces out of go-bar jig being trimmed and sanded

3. Back and braces out of go-bar jig being trimmed and sanded

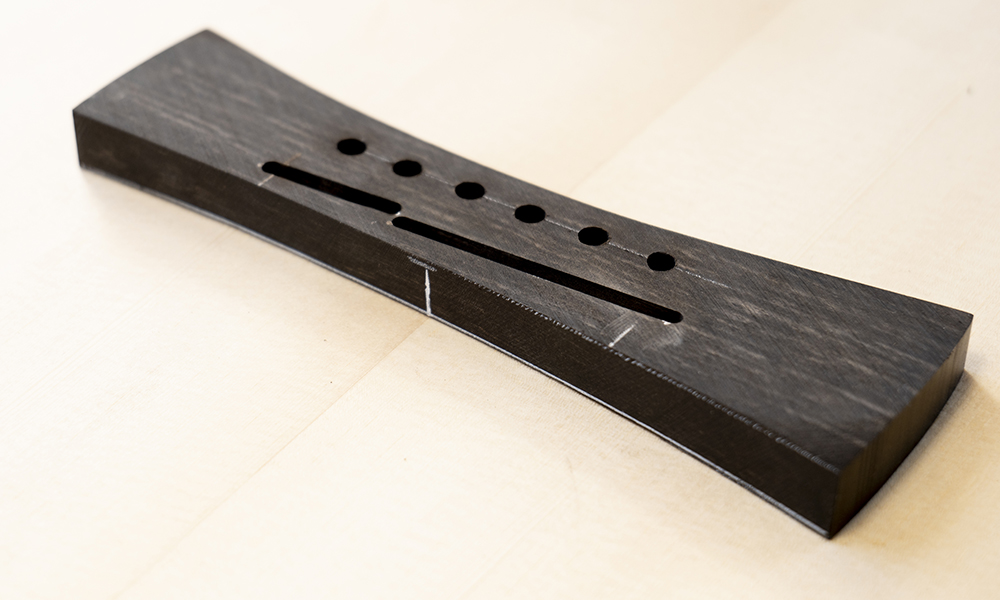

Bridge shaped to soundboard curve, drilled and slotted

Bridge shaped to soundboard curve, drilled and slotted Bridge in its final shape. Writing identifies it as individually made to fit this guitar

Bridge in its final shape. Writing identifies it as individually made to fit this guitar